Significant Cost Reduction in Manufacturing

The Power Of Energy Monitoring

Funded By:

Funded By:

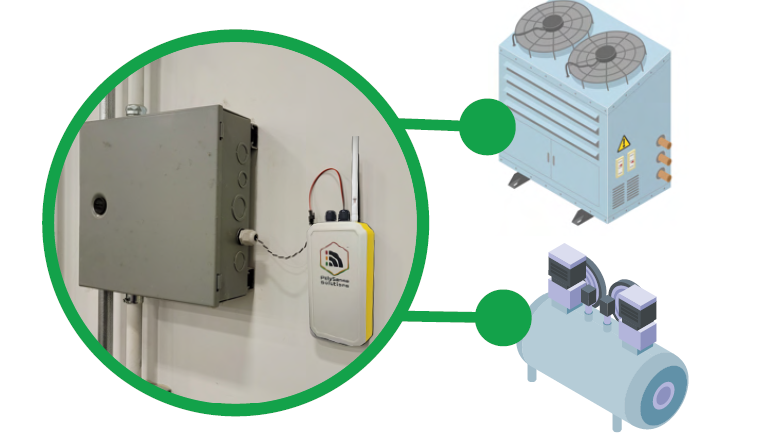

In this case study, PolySense Solutions used its proprietary AMP/BOLT technologies to monitor energy usage and utilization of 24 machines at a small manufacturing facility in Winnipeg, Manitoba.

Over the first two months of monitoring, PolySense was able to

identify potential energy savings of $8500 annually, which

represents a substantial 28% reduction in their current annual

electricity expenditure. The majority of these savings were

attributable to inefficiencies in three key machines - an air

compressor, a wire electrical discharge machining (EDM) unit, and a

rooftop HVAC unit.

The main air compressor was found to be operating at nearly 100%

duty cycle due to several system leaks. In addition, the wire EDM

machine was discovered to be left on standby mode and was never

completely powered down, contributing to significant unnecessary

energy expenditure. The rooftop unit was improperly programmed, with

a poorly set thermostat leading to high power usage.

If these issues are rectified, energy consumption for these machines

should be dramatically reduced. This client also benefitted from

better visibility into their operations and equipment utilization

due to the automatic data capture and reporting on the PolySense

Platform

This case study illustrates the potential for significant energy

savings in similar facilities through the use of advanced monitoring

technologies like AMP and BOLT.

Estimated Electricity Savings = $6000/year

Estimated

Additional Savings = $1200

Changes to implement: PolySense Solutions found and measured 8 significant air

leaks. Repairing these leaks will have a substantial impact

on energy costs and equipment lifetime

Estimated Electricity Savings = $500/year

Estimated

Additional Savings = $120/year + reduced maintenance

Changes implemented:

Thermostat was found to be on hold A/C mode 24/7.

Adjusted thermostat temperature and schedule so that a

reasonable temperature was held during regular hours, and

evenings.

Estimated Electricity Savings = $2000/year

Estimated

Additional Savings = $2000

Changes to implement:

Shut the machine down at the end of each day. This

machine was found to use over 3100 watts when sitting idle.

Although there may be a few instances throughout the year

where the machine needs to run for a few hours overnight,

increasing the frequency of shutdowns will lead to

substantial savings

Reducing the duty cycle of both the air compressor and the Wire EDM unit from 100% to 30% for the remainder of their lifespan offers substantial economic advantages. By modifying the duty cycle, we extend the useful life of these units, thereby optimizing the return on the initial investment.

The ultrasonic leak detector helped us find the leaks in a noisy manufacturing shop environment. Once close, we could hear the leaks with our ears, and in some cases feel them with our hands. The leaks are severe enough that the air compressor is constantly running to compensate.

In conclusion PolySense Solutions, employing its advanced AMP/BOLT

technologies, illustrated significant potential for energy savings

in the manufacturing industry. Our intervention at this

manufacturing facility allowed us to swiftly and non-invasively

pinpoint inefficiencies, culminating in direct annual energy savings

of $8500 if suggested changes in this report are implemented, which

represents a substantial 28% reduction in their current annual

electricity expenditure. These savings primarily arose from

rectifying operational issues in three key pieces of machinery: an

air compressor, a wire EDM unit, and a rooftop HVAC unit.

Additionally, addressing these issues will contribute to an

indirect cost saving of $3200 for the client in the form of reduced

maintenance on this equipment.

Moreover, our initiatives have considerably reduced the load

on the electrical grid by 90,000 kWh each year, fostering

environmental sustainability and enhancing the stability of the

grid.

Our technology also enhanced the client’s operational

visibility, enabling more effective management and optimal

utilization of their equipment.

This case study underscores the transformative value that

advanced monitoring technologies like our AMP & BOLT can offer to

energy-conscious organizations, with substantial direct and indirect

financial savings, environmental benefits, and operational

efficiencies.

Get the latest news and updates from PolySense

HQ:

3 - 363 Broadway, Suite 312

Winnipeg, MB, R3C 3N9, CA

R&D:

441-100 Innovation Drive

Winnipeg, MB, R3T 6G2, CA